Design Consultations

PILLAR offers expert guidance in selecting the ideal fittings and weldment configurations tailored to your custom applications.

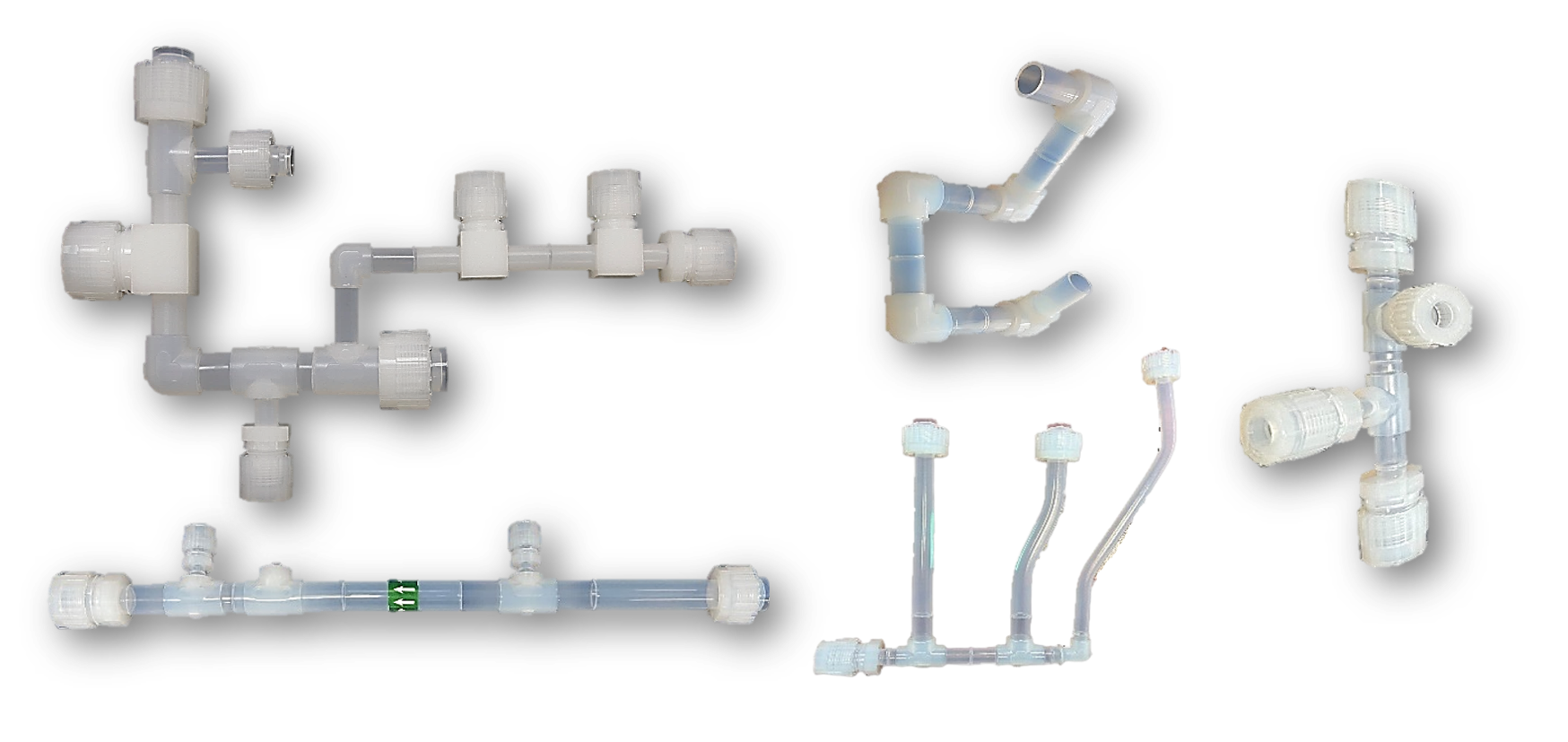

PILLAR provides comprehensive manufacturing and design services for weldments and bent tubes, tailored to meet the precise needs of our customers.

Custom PFA weldments and bent tubes are vital components of semiconductor process tools, ensuring the efficient delivery of chemicals for wafer processing in all fab tools.

PILLAR offers expert guidance in selecting the ideal fittings and weldment configurations tailored to your custom applications.

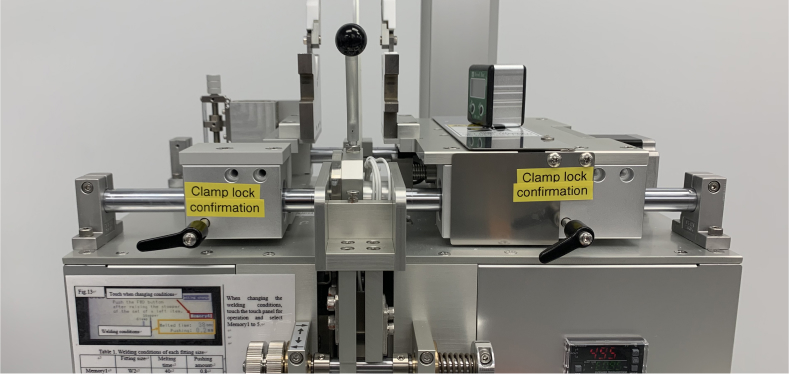

All of PILLAR’s welding and bending machines are fully automated, ensuring superior quality and productivity for even the most critical features.

Assemblies undergo 100% inspection, including pressurized leak testing, thermal testing, and dimensional inspection, to ensure the highest quality standards.

Every step, from component procurement to shipment, is carried out within a cleanroom environment to ensure the highest level of cleanliness.

PILLAR serves all-custom needs for weldments and bent tubes.

Our in-house design, standard products, secondary labor, testing, and warranty services streamline processes, reducing costs and lead times for faster product launches.

Our automated manufacturing processes, vertical integration, and rigorous quality control instill confidence in our customers, ensuring a reliable and trusted partnership.

Manufactured, tested, inspected and packed in Class 10000 (ISO 7) cleanroom.

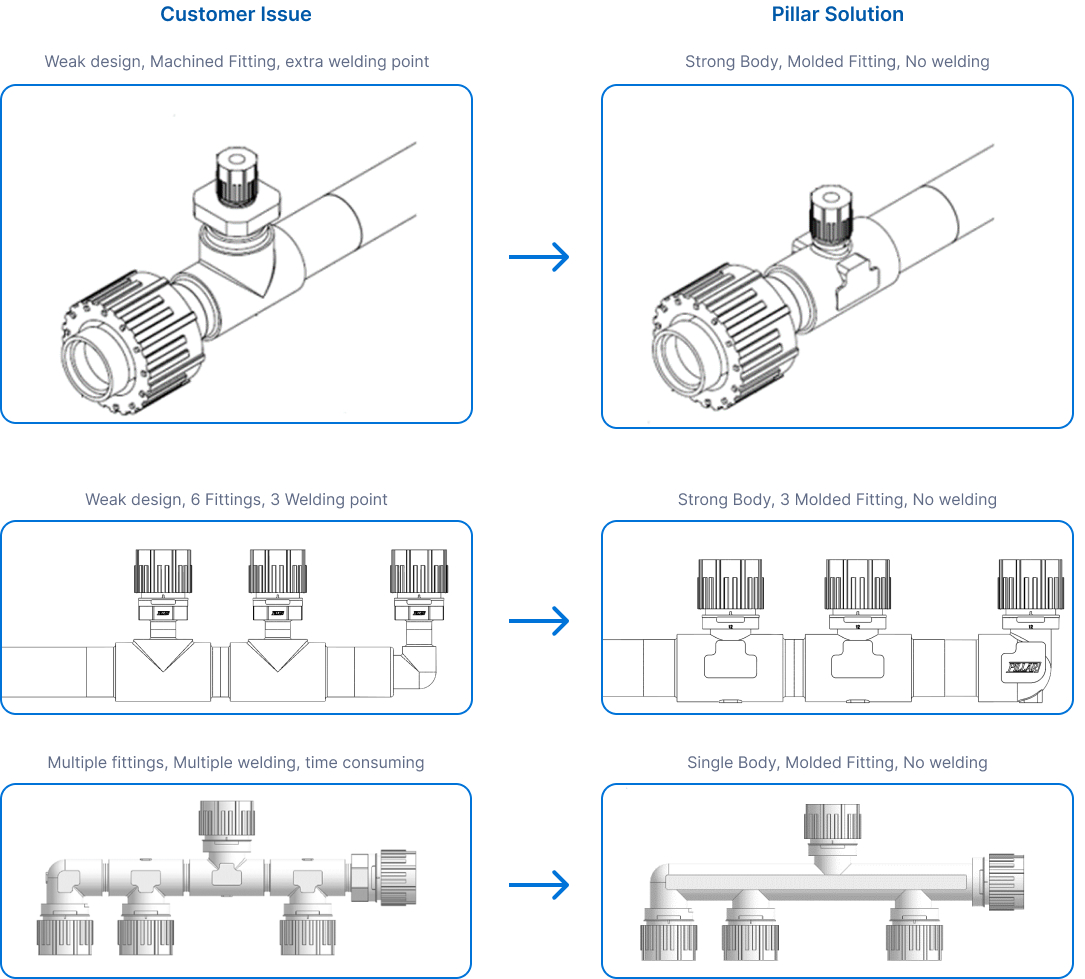

PILLAR can offer value-added solutions to streamline design & production.

Here are few case-study examples of our customers’ past challenges.