Our API Seals are custom-engineered to meet the demanding requirements of the oil and gas industry, designed to withstand extreme pressures and temperatures. More than just components, they play a crucial role in ensuring operational continuity and environmental compliance. Built to API and ANSI standards, these heavy-duty seals deliver reliable, tailored performance for your specific needs.

PILLAR Engineered Seal

FEATURES

- Ensures stable sealing under high velocity, pressure, and fluctuation

- Features a bilaterally symmetrical floating ring for pressure fluctuation

- Static type structure suitable for extremely high load conditions

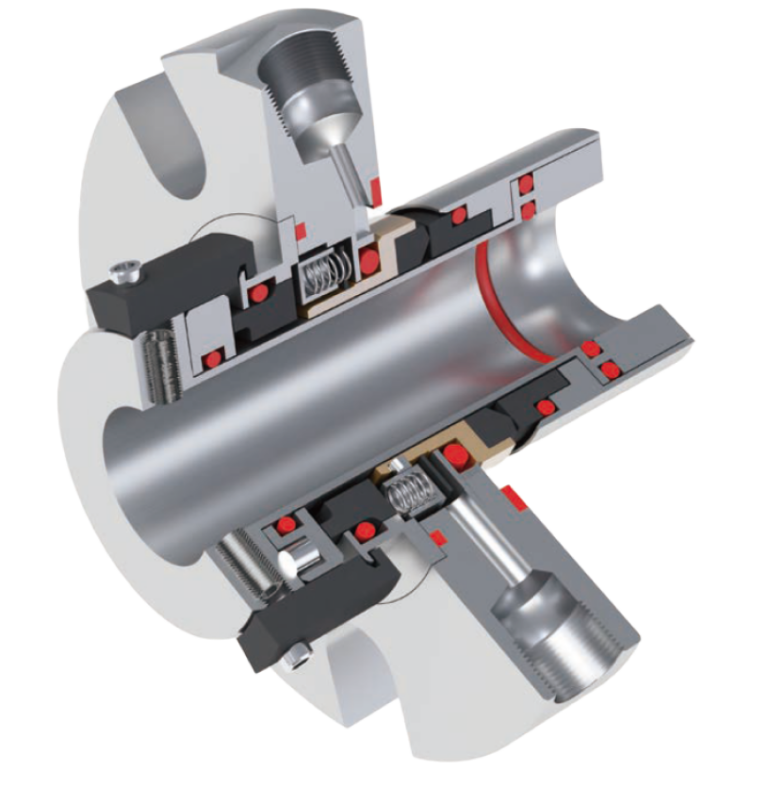

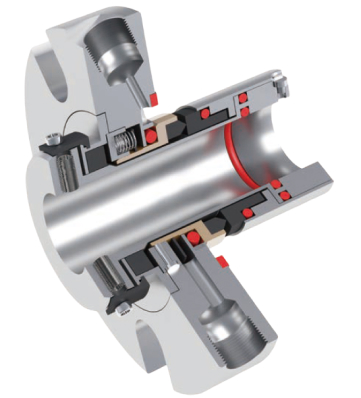

Cartridge Seal with Knife Edge Technology

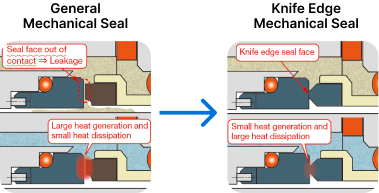

Our Knife Edge Seals outperform conventional mechanical seals in handling high-viscosity liquids. Featuring a narrow face width, they effectively prevent liquid accumulation and cut through coagula, maintaining a tight seal against the shaft. Designed to generate minimal heat while providing superior heat dissipation, these seals offer enhanced cooling and sealing performance, making them a reliable solution in demanding conditions.

FEATURES

- Highly Reliable Static Seal Design: Features an integrally designed sleeve that avoids shaft wear and ensures stable, long-term performance.

- Superior Material Choice: Utilizes Silicon Carbide (SiC) for the seal face, offering excellent wear resistance, chemical resistance, and extended service life.

- Four-Action Installation: Designed for easy installation without prior assembly experience, simplifying the replacement process.

- Diverse Product Lineup: Includes various models like type GAKEM for knife edge sealing, type GABE5 for high pressure, type GXKEM for high-concentration slurry, and a tandem seal type for specialized applications.

Phoenix-Seal™

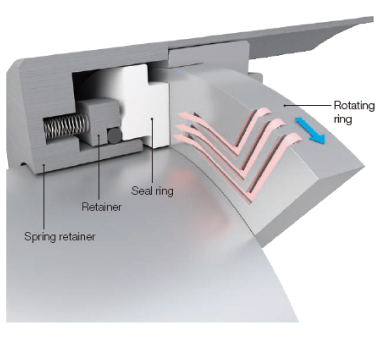

The PILLAR Phoenix-Seal utilizes advanced aerodynamic technology to provide exceptional containment in critical applications. This innovative non-contact dry gas seal leverages dynamic pressure generated by grooves on the rotating ring to maintain a micro-scale gap, reducing leakage to less than 0.1% compared to traditional seals. Operating without physical contact, it minimizes power consumption and extends service life, while remaining lubricating oil-free for superior performance and reliability, particularly in emergency situations.

FEATURES

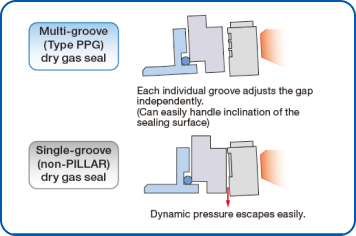

- Multi-Groove Design: multiple independent grooves that support bidirectional rotation, enhancing dynamic pressure retention, which boosts reliability and safety.

- Automatic Gap Adjustment: Utilizes a dynamic pressure mechanism that automatically adjusts the gap width to maintain a balanced state, continuously floating the seal ring by several micrometers.

- Aerodynamic Non-Contact Mechanism: engraved grooves on the rotating ring to generate dynamic pressure, keeping the seal ring floating minimally to drastically reduce liquid leakage—less than 0.1% compared to labyrinth seals.

- Energy Efficient and Durable: Maintains a non-contact state during operation to minimize motive power consumption. Also features lubricating oil-free operation and a prolonged service life, emphasizing efficiency and sustainability.

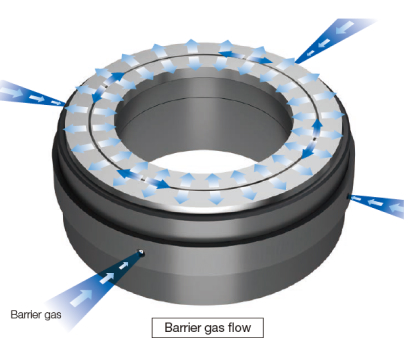

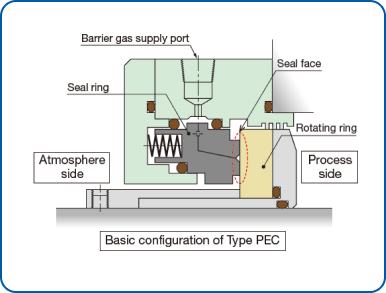

Aerostatic Dry Gas Seal Type PEC

The PEC Seal uses barrier gas—such as nitrogen or dry air—supplied externally to establish a static pressure barrier. This system maintains a floating gap of several to tens of micrometers between the seal faces, reducing leakage to just 1/1000th of that found in labyrinth seals. With automated gap control for enhanced reliability, the PEC Seal is ideally suited for high-speed applications in dispersers, blowers, compressors, and mixers. Engineered to support high-speed rotations without wear debris, the Type PEC seal ensures cleanliness and safety, making it perfect for industries handling sensitive or hazardous materials.

FEATURES

- Completely sealed with a single seal: Process gas is completely sealed with a single seal. Not only does this product contribute to ensuring safety and environmental friendliness.

- High level of cleanliness: Compared to double mechanical seals and dry-contact seals, which have been conventionally used as shaft seals for gases, this product does not leak confined liquid into the process side or produce wear debris.

- Wide speed range: This product can continuously retain its seal face in a non-contact state and can therefore handle various shaft states from a stopped state through to a high-speed rotation state.

- Long service life: This product maintains its seal face in a non-contact state and therefore protects the seal face from wear and damage, extending service life.