High quality repair services restoring products to like-new condition. We are committed to servicing API682 along with most types and models of seals.

PILLAR offers fast turnaround and high-quality service.

High quality repair services restoring products to like-new condition. We are committed to servicing API682 along with most types and models of seals.

PILLAR offers fast turnaround and high-quality service.

We stand by the quality of our work with a warranty on all repaired seals. This ensures peace of mind and confidence in the durability and reliability of your equipment after servicing

Our repair process begins with a detailed failure analysis to pinpoint the root cause of your mechanical seal issues. We provide clients with comprehensive reports that highlight the underlying problems, helping you address operational inefficiencies and prevent recurring failures.

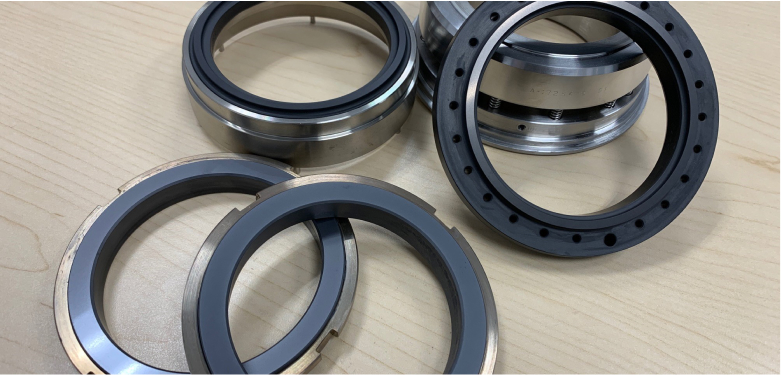

To ensure the longevity and optimal performance of your mechanical seal, we carefully inspect and replace all worn or damaged consumable parts during the repair process. This includes components such as O-rings, gaskets, and springs, which are critical to maintaining reliable operation. By using high-quality, OEM-specified replacement parts, we restore your seal to like-new condition, minimizing the risk of future failures and maximizing efficiency in your operations.

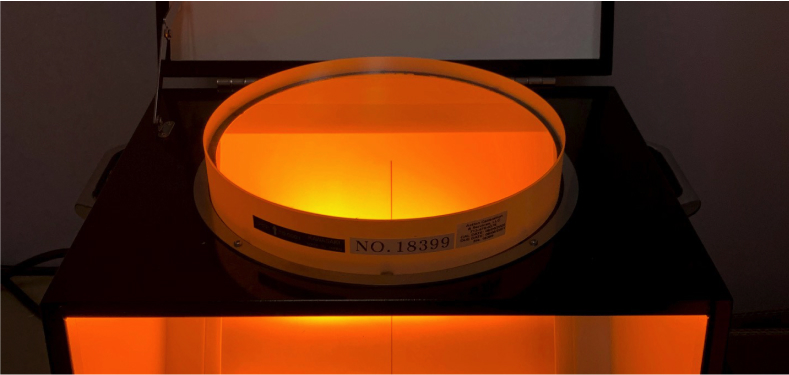

With the precision of Kemet lapping and polishing machines, operated by our experienced technicians, we restore seal face flatness to meet original specifications. This reliable and proven equipment ensures your mechanical seals are refurbished to the highest standards, delivering exceptional performance in demanding applications.

Every seal undergoes a meticulous post-repair inspection to ensure it meets the highest standards of quality and reliability. This process includes API 682-compliant air testing, verifying the seal’s integrity and operational performance. A detailed report is provided, outlining the repair work and test results, giving you full transparency and confidence in the seal’s readiness for demanding applications.

High quality services to restore products

Competitive prices and fast turnaround time

Servicing API682 and most models of seals

Quality service provided by PILLAR engineers

PILLAR pumps are designed to efficiently deliver liquids to machine tools in semiconductor fabs or transfer chemicals. Ensuring your pumps remain in top condition is essential for optimal performance and reliability.

At our Houston facility, we provide comprehensive pump maintenance and repair services, including:

Every repaired pump is returned with a detailed repair report and certification, providing you with confidence in its performance and compliance.

Proper handling is critical to ensure the longevity and reliability of PILLAR pumps. Our certified technicians, trained and authorized by PILLAR headquarters, are equipped to carefully disassemble and repair pumps to the highest standards.

All repair work is carried out in ISO Class 7 cleanrooms featuring controlled positive-pressure environments. This stringent contamination control helps maintain pump integrity and ensures compliance with the highest industry standards. Our dedicated spaces include:

With these industry-leading facilities, we are equipped to repair all of the PILLAR pump lineup, delivering results that consistently meet customer expectation and industry standards.

By combining certified technicians, rigorous quality controls, and cleanroom-level repair conditions, we provide expert service that safeguards your equipment’s reliability and operational excellence.

Every pump we service is handled with meticulous care and attention to detail. Our methodical process and fine-tuned repair techniques ensure that each pump returns to your operation performing at peak capacity, delivering the consistent, reliable results you need.

Our team is trained and certified directly by PILLAR headquarters, giving you the assurance that your pumps are in expert hands. Their first hand knowledge of pump mechanics and compliance standards means that every repair is executed with maximum professionalism and competence.

Repairs are conducted in ISO Class 7 cleanrooms designed to maintain strict contamination control. We preserve the purity and integrity of your equipment.

When a unit ultimately reaches the end of its serviceable lifespan, our team follows environmentally responsible disposal procedures. By upholding sustainable practices and strict compliance measures, we help you maintain an operation that’s both efficient and respectful of our shared environment.